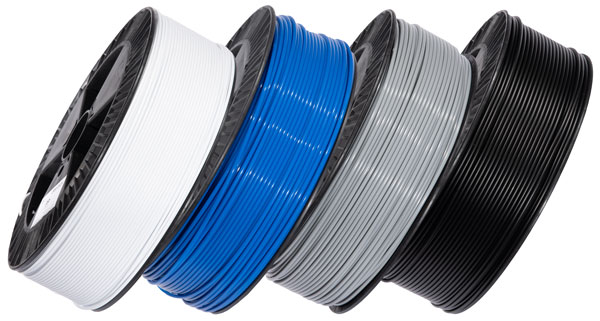

ABS

Acrylonitrile Butadiene Styrene

Thermoplastics can be welded. Thermoplaste sind Werkstoffe wie zum Beispiel ABS, PC, PE, PP, PS.

It is important to always use the correct welding rod. To do this, choose a rod made of the same plastic as the part you want to weld.

You can weld plastics with a hot air tool, an Injectiweld or an extruder.

The joining part and the welding rod are melted and joined under pressure. The result is a stable and reliable connection.

They can weld all thermoplastics.

Thermoplastics are materials that melt when exposed to heat. Thermosets do not melt and can only be glued.

Always use a plastic welding rod of the same type. As an example, use a PE rod if you want to weld parts made of Polyethylene.

You will find a marking on most plastic parts (usually on the back or bottom).

You can also easily determine the plastic by performing a test weld. Only materials of the same type establish a solid bond. An unsuitable welding rod will not hold to your joining part.

We explain the process in more detail here.

A hot air tool with temperature and air volume control is the first choice. You are flexible with a hot air tool and can also weld hard-to-reach places.

For professional use, especially for larger welds, the Injectiweldor a hand extruder are used. These machines pull in the plastic welding rod automatically and apply the molten material onto your joining parts.

You make repairs of small or thin parts with a welding iron. A heated tip is used to melt the damaged area, such as a crack, and then material is applied.

Tools, which are suitable for plastic welding, can be adjusted in temperature.

Temperatures between 240 and 270 °C are a good choice for most plastics. Technical materials such as PA / nylon or ABS require higher temperatures. We recommend, to always stay below 300 °C, otherwise plastics will oxidize and the molecular structure will be damaged. The durability of the weld seam can then not be reliably relied upon and, under certain circumstances, even harmful gases can be generated.

Clean the area thoroughly in which you are going to weld. And work in a well-aerated area.

Always remove the oxide layer in the area of the weld. This can be achieved, for example, by mechanically removing a thin layer with a scraper or metal blade. You can also sand the surface.

Weld with calm and patience. The plastics need time to melt. Too high temperatures only reduce the durability of the weld. You can re-melt and rework the weld at any time. So there is no need to rush.

We will gladly manufacture welding rod according to your requirement.

Optionally also from your own material.

You will find informations about the custom production here.

The spool with welding rod is put on the unroll stand and the rod is fed through the opening on the side.

You will unwind the rod without overlapping, tangling or knotting.

The rotary movement is slightly braked, so that the spool does not roll on uncontrolled, but stops when the welding rod is no longer pulled.

| Material | Dichte | Erweichungstemperatur | Erweichungstemperatur | Zugfestigkeit | Streckdehnung | E-Modul | E-Modul | Schweißtemperatur | Trocknen | Trocknen | Schweißdraht |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ABS | 1,05 g/cm3 | 100 °C | 100 | 45 MPa | 2,6 % | 2.190 MPa | 2190 | 255 - 310 °C | 85 °C 2-5 h | 85 | Shop |

| smartABS | 1,09 g/cm3 | 100 °C | 100 | 40 MPa | 2,7 % | 2.040 MPa | 2040 | 255 - 300 °C | 80 °C 2-3 h | 80 | |

| ABS/PC | 1,1 g/cm3 | 110 °C | 100 | 55 MPa | 50 % | 2.590 MPa | 2590 | 275 - 320 °C | 90 - 110 °C 2-4 h | 90 | |

| ASA | 1,07 g/cm3 | 110 °C | 110 | 55 MPa | 3,5 % | 2.590 MPa | 2590 | 255 - 310 °C | 85 °C 2-4 h | 85 | Shop |

| HiPS | 1,04 g/cm3 | 95 °C | 95 | 25 MPa | 1,5 % | 1.990 MPa | 1990 | 255 - 300 °C | 80 °C 2-3 h | 80 | Shop |

| Moldlay | 1,18 g/cm3 | 55 °C | 55 | 42 MPa | 20 % | 1.950 MPa | 1950 | 70 °C 1-3 h | 70 | ||

| Nylon / PA | 1,01 g/cm3 | 140 °C | 140 | 40 MPa | 5,0 % | 1.390 MPa | 1390 | 265 - 320 °C | 85 °C 3-5 h | 85 | Shop |

| PC | 1,2 g/cm3 | 140 °C | 140 | 65 MPa | 6,0 % | 2.390 MPa | 2390 | 275 - 310 °C | 120 °C 4 h | 120 | Shop |

| PE | 0,95 g/cm3 | 70 °C B | 70 | 22 Mpa | 10 % | 1.000 MPa | 1000 | 245 - 285 °C | Shop | ||

| PET | 1,29 g/cm3 | 78 °C | 78 | 50 MPa | 4,0 % | 2.970 MPa | 2970 | 245 - 285 °C | 70 °C 6 h | 70 | |

| PP | 0,9 g/cm3 | 140 °C | 140 | 20 MPa | 50 % | 1.140 MPa | 1140 | 250 - 285 °C | Shop | ||

| PVC | 1,4 g/cm3 | 74 °C B | 74 | 58 MPa | 4,0 % | 3.300 MPa | 3300 | 250 - 280 °C | 70 °C 1-3 h | 70 | Shop |

| TPE | 0,97 g/cm3 | 250 - 270 °C | 80 °C 2-4 h | 80 | Shop | ||||||

| TPU | 1,2 g/cm3 | 40 MPa | 600 % | 12 Mpa | 12 | 250 - 270 °C | 100 °C 1-2 h | 100 |