ABS

Acrylonitrile Butadiene Styrene

Polypropylene is a semi-crystalline thermoplastic. PP is harder and more heat resistant than PE. Polypropylene is the second most widely used plastic in the world. Packaging and industrial goods are made of this material.

Compared to PE, PP has better mechanical properties and a higher thermal resistance. Foil hinges can be made from PP. PP is resistant up to a temperature of ~110°C.

Polypropylene has good resistance to chemicals. It is resistant to grease, many solvents, acids and alkalis, and alcohol. PP hardly absorbs any water. Gases diffuse through PP.

Polypropylene does not bond or print well without pretreatment. We weld to join parts made of PP.

Polypropylene can be post-processed very well by drilling, grinding, sawing and machining.

There are three types of Polypropylene: the homopolymer has particularly good stiffness, the copolymer has high impact strength, and the random copolymer has high transparency.

PP is the second most common material. You can post-process PP well by sawing, grinding, drilling and machining.

PP has high resistance to many chemicals and good mechanical strength.

PP is a non-polar material. For this reason, we recommend abrading the surface in the joining area.

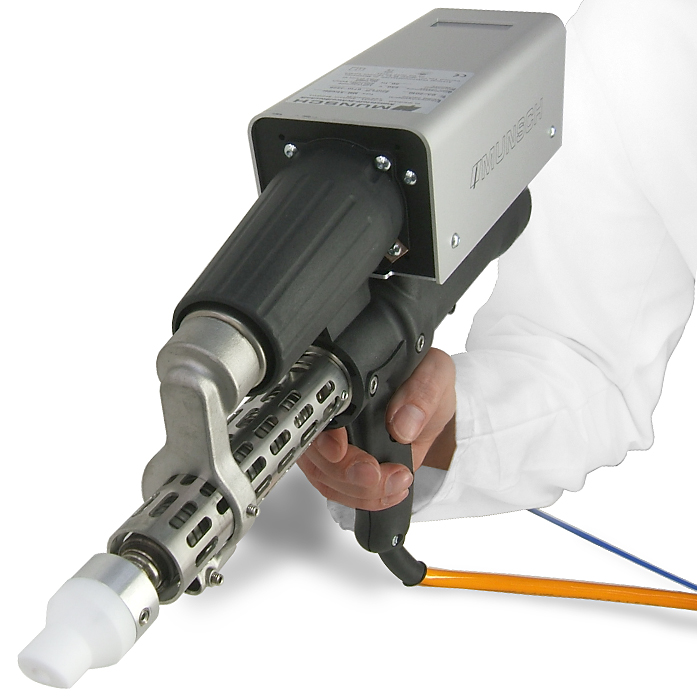

You can use all standard welding equipment. A hot air tool, an injectiweld or extruder.

PP is easy to post-process. It can be drilled, sawed, machined and varnished.

Acrylonitrile Butadiene Styrene

Acrylonitrile Butadiene Styrene / Polycarbonat

Acrylonitrile-Styrene-Acrylate-Copolymerizate

Polyamide / Nylon

Polycarbonate

Polyethylene

Polypropylene

Polypropylene EPDM

soft PP

Polystyrene

Polyvinyl Chloride

thermoplastic elastomer