ABS

Acrylonitrile Butadiene Styrene

You always use a welding rod made of the same type of plastic for welding plastic.

ABS is welded to ABS, PE to PE and PP to PP.

Many plastic parts are stamped with a material stamp, the letters of which indicate the plastic used.

A weld test will help if you cannot find a material stamp or if you do not want to dismantle the plastic part to be repaired.

During the welding test, you melt the plastic part. At the same time, you also melt a rod that you suspect might be the right welding rod. Hold the melts in each other. If the rod sticks after cooling down, this is the right welding rod.

You can easily determine the right welding rod with the welding iron.

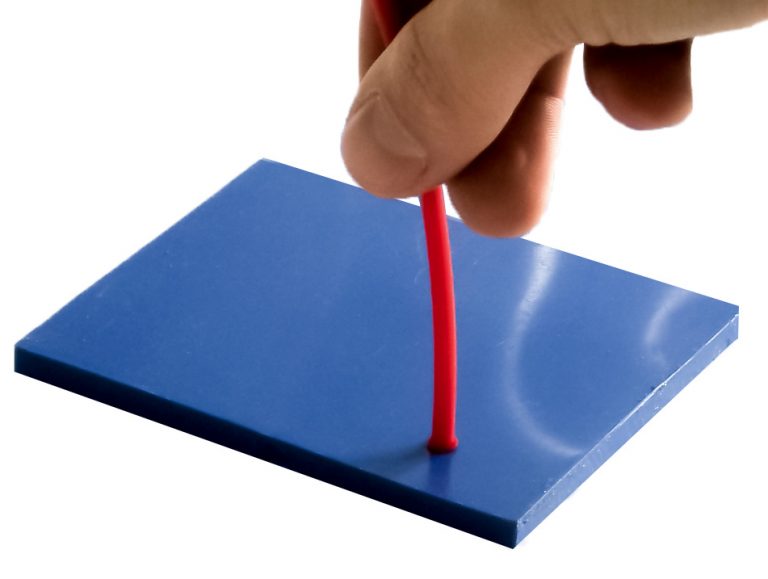

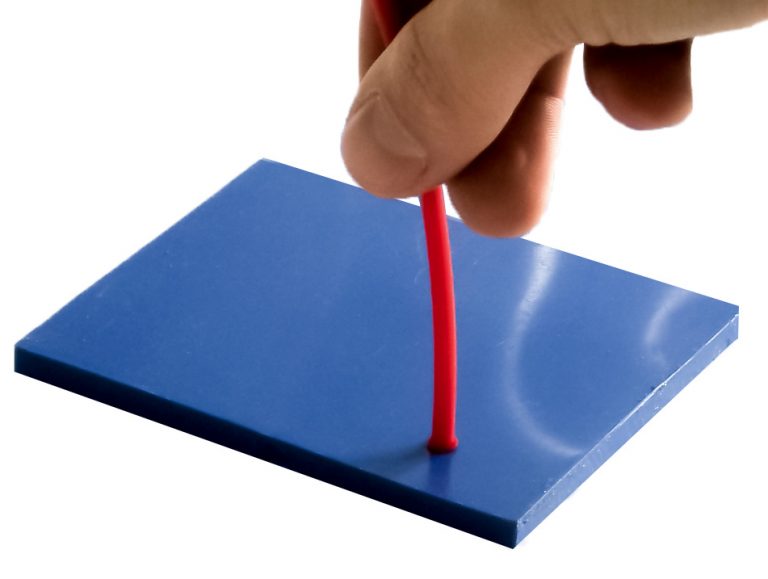

Place the hot welding tip from the welding iron on the plastic part.

Hold a welding rod on the top of the welding tip at the same time.

Now watch how both plastics melt.

When both plastics have melted, carefully pull the tip away to the side.

Immediately press the welding rod vertically onto the plastic part. Apply a gentle but not too strong pressure so that the melt is not pushed away to the side.

Leave the joint to cool down.

You have determined the correct welding rod if you cannot detach the welding rod by pulling or kinking it.

First remove the oxide layer from the plastic part. Do this with a scraper or by sanding. Now you can weld onto a fresh plastic surface.

Now weld a few centimetres of an approx. 20 cm long welding rod onto the plastic part with the welding shoe or by fanning welding.

Leave the joint to cool down.

Now try to pull the welding rod off the surface.

Sie haben den richtigen Schweißzusatz bestimmt, wenn der Schweißdraht auf der Oberfläche hält.

Acrylonitrile Butadiene Styrene

Acrylonitrile Butadiene Styrene / Polycarbonat

Acrylonitrile-Styrene-Acrylate-Copolymerizate

Polyamide / Nylon

Polycarbonate

Polyethylene

Polypropylene

Polypropylene EPDM

soft PP

Polystyrene

Polyvinyl Chloride

thermoplastic elastomer