ABS

Acrylonitrile Butadiene Styrene

Polystyrene is an amorphous thermoplastic. The normal PS is hard, rigid and sensitive to impact.

Our welding rod is made of Hi-PS. The high-impact variant of polystyrene has better impact strength.

Polystyrene is used in electrical engineering because of its good electrical resistance values.

PS is resistant to moisture, salt solutions, and weak alkalis and acids. This plastic is not resistant to non-polar solvents. Polystyrene is sensitive to UV radiation and becomes brittle quite quickly when exposed to light.

In 3D printing, HiPS can be processed very similarly to ABS. HiPS is used as a support material for 3D objects made of ABS, because the polystyrene can be dissolved and removed with limonene.

Polystyrene is used to make electronic housings and plastic sheets from the DIY store.

HiPS is suitable as a support material for 3D printing and can be dissolved with limonene.

Polystyrene is a hydrophilic material. We recommend tempering the welding rod before processing for this reason.

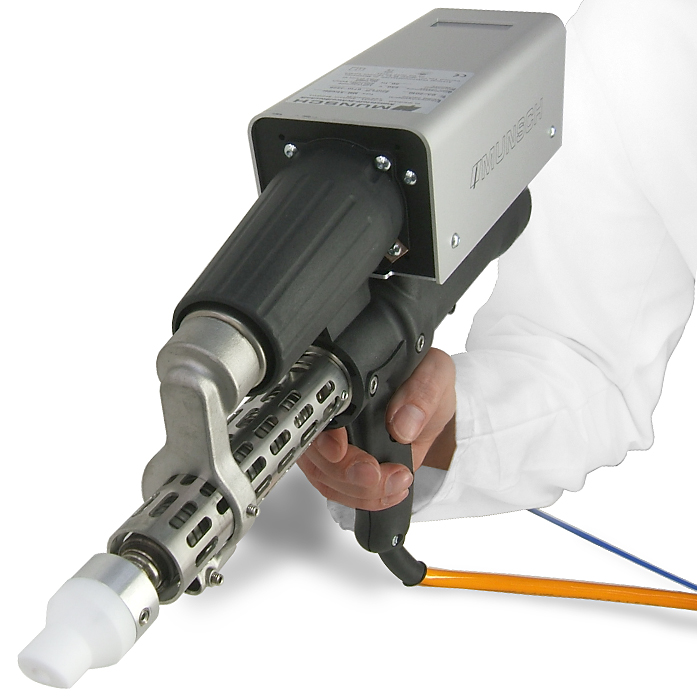

You can use all standard welding equipment. A hot air tool, an injectiweld or extruder.

PS lässt sich gut nachbearbeiten. It can be sanded, painted and glued.

Acrylonitrile Butadiene Styrene

Acrylonitrile Butadiene Styrene / Polycarbonat

Acrylonitrile-Styrene-Acrylate-Copolymerizate

Polyamide / Nylon

Polycarbonate

Polyethylene

Polypropylene

Polypropylene EPDM

soft PP

Polystyrene

Polyvinyl Chloride

thermoplastic elastomer