ABS

Acrylonitrile Butadiene Styrene

Polyamide is a semi-crystalline polymer commonly referred to as Nylon.

Polyamide has extremely high strength and toughness. To tear or break this material is very difficult. Items that have to withstand high mechanical stress are often made of Polyamide. Polyamide also has good resistance to heat.

The abbreviated designation PA is supplemented by a number. This provides information about the number of carbon atoms. Commonly used are PA-6 and PA-12. PA-12 has only one tenth of the water absorption of PA-6. In principle, polyamides must be very well dried for processing.

The high impact strength, high notched impact strength and good sliding properties are the greatest advantages of Polyamide. Moisture absorption makes the application challenging.

We know polyamide from products such as cable ties or from the bristles of a toothbrush. Ropes, plastic screws, gears, parts from the engine interior (often fiber-reinforced) and fuel tanks and lines. Stable threads can be cut into parts made of polyamide. Polyamides are oil-resistant.

High-strength objects result in 3D printing, making nylon an exciting 3D filament.

Nylon is an extremely strong and stressable material for parts exposed to high mechanical stress.

Nylon has a very high strength and temperature resistance.

Nylon is a very hydrophilic material. We recommend tempering the welding rod before processing for this reason.

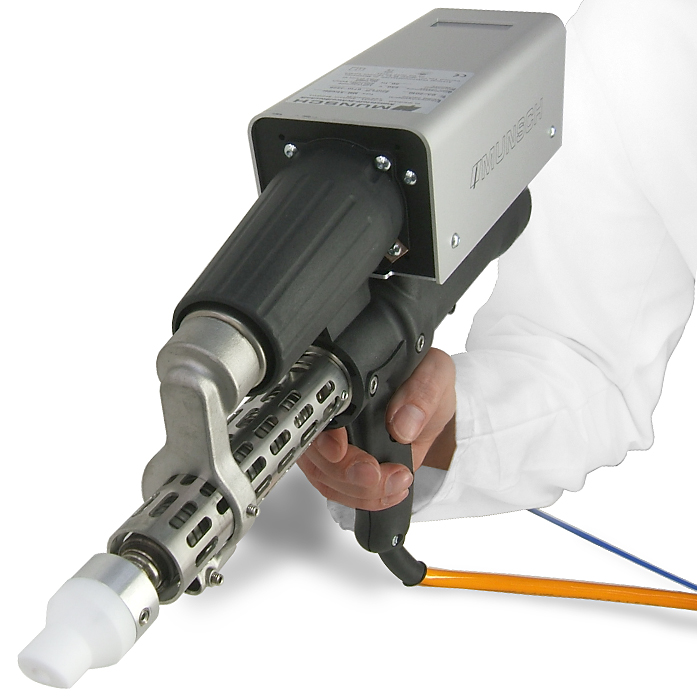

You can use all standard welding equipment. A hot air tool, an injectiweld or extruder.

Nylon gives you mechanically and thermally highly stressable parts in which a stable thread can also be cut.

Acrylonitrile Butadiene Styrene

Acrylonitrile Butadiene Styrene / Polycarbonat

Acrylonitrile-Styrene-Acrylate-Copolymerizate

Polyamide / Nylon

Polycarbonate

Polyethylene

Polypropylene

Polypropylene EPDM

soft PP

Polystyrene

Polyvinyl Chloride

thermoplastic elastomer