ABS

Acrylonitrile Butadiene Styrene

Acrylonitrile-Styrene-Acrylate is an amorphous copolymer consisting of the three components Acrylonitrile, Styrene and Acrylic acid ester.

This engineering plastic has similar properties to ABS. The weather resistance and UV resistance is better with ASA. For this reason, parts made of ASA are more suitable for outdoor use.

ASA is a hard material with very good technical properties. The material is very impact resistant and scratch resistant. The surface is more glossy than ABS.

ASA is very suitable for varnishing and coating. It can be well post-processed by sanding, sawing and drilling.

Chemical resistance to oils and greases, alcohol and weak acids also make this plastic interesting for many applications.

ASA plastic is often used for parts that are thermally stressed or exposed to the weather. So we find ASA in electrical appliances such as a coffee maker or a microwave, in articles from the sports and recreational sector and especially often in parts of automobiles.

ASA is a very proven material for 3D printing as a 3D filament.

ASA is often used. You can finish it well afterwards; by grinding and drilling. And you can varnish it.

ASA has high strength and temperature resistance and very good weather resistance.

ASA is a hydrophilic material. We recommend tempering the welding rod before processing for this reason.

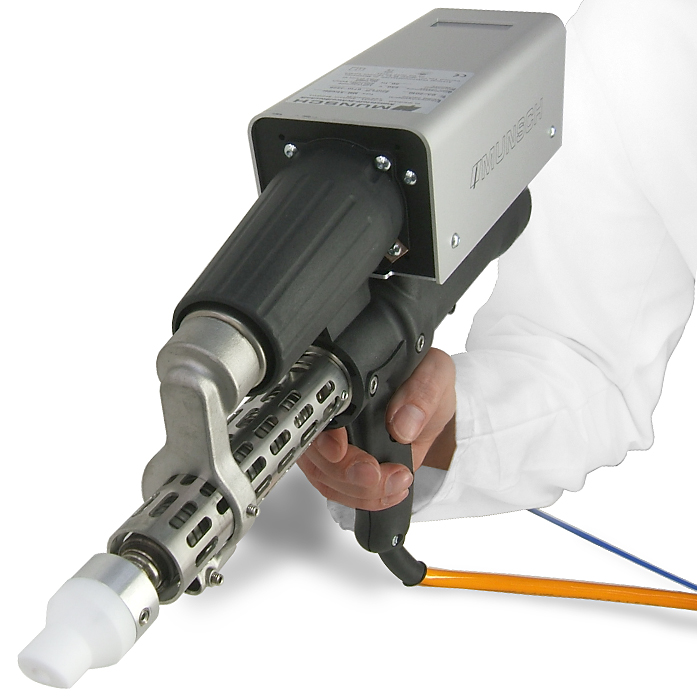

You can use all standard welding equipment. A hot air tool, an injectiweld or extruder.

ASA is easy to post-process. It can be sanded, painted and galvanized.

Acrylonitrile Butadiene Styrene

Acrylonitrile Butadiene Styrene / Polycarbonat

Acrylonitrile-Styrene-Acrylate-Copolymerizate

Polyamide / Nylon

Polycarbonate

Polyethylene

Polypropylene

Polypropylene EPDM

soft PP

Polystyrene

Polyvinyl Chloride

thermoplastic elastomer