ABS

Acrylonitrile Butadiene Styrene

PP-EPDM consists mostly of polypropylene and part of a softer elastomer.

Parts made of PP-EPDM are more flexible than those made of pure PP. For this reason, bumpers or wheel arches on cars are preferably made from this plastic.

PP-EPDM is chemically resistant to many acids, alkalis, oils and greases.

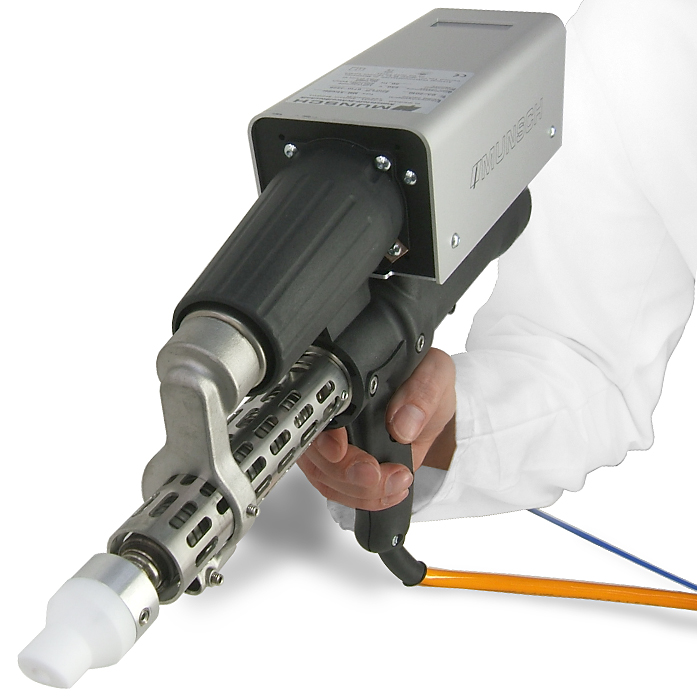

PP-EPDM can be welded reliably. For parts from the car you use a welding iron otherwise a hot air tool, an Injectiweld or an Extruder.

PP-EPDM is used to make bumpers and wheel arches on cars.

PP-EPDM is softer and more flexible than pure PP.

PP-EPDM is a non-polar material. For this reason, we recommend abrading the surface in the joining area.

You can use all standard welding equipment. A hot air tool, an injectiweld or extruder.

PP-EPDM can be easily post-processed. It can be drilled, sawn, machined and varnished.

Acrylonitrile Butadiene Styrene

Acrylonitrile Butadiene Styrene / Polycarbonat

Acrylonitrile-Styrene-Acrylate-Copolymerizate

Polyamide / Nylon

Polycarbonate

Polyethylene

Polypropylene

Polypropylene EPDM

soft PP

Polystyrene

Polyvinyl Chloride

thermoplastic elastomer