ABS

Acrylonitrile Butadiene Styrene

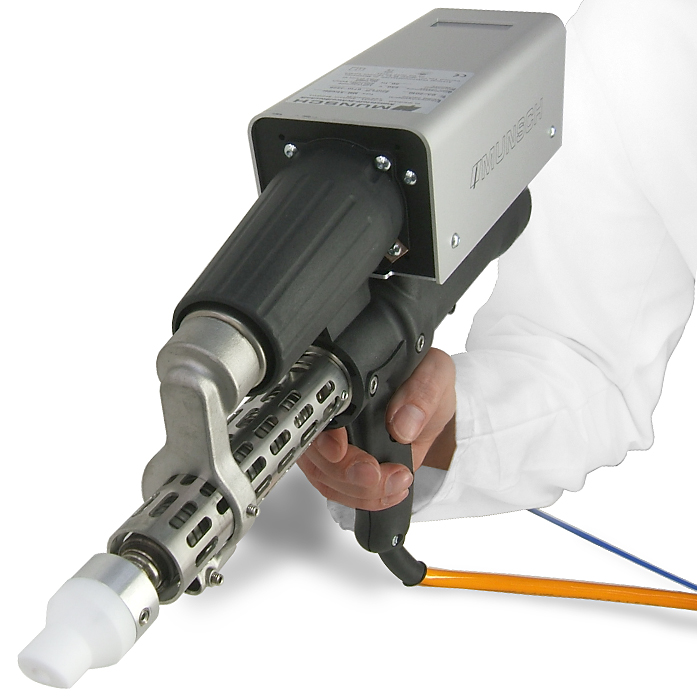

The Drader 245 is a very small and handy welding machine for plastics.

The three interchangeable welding tips are made of metal and are heated.

The Drader 245 is operated by hand. This makes it very light.

The welding rod is conveyed by squeezing the handle.

If you are looking for a small and lightweight plastic welder and want to carry out repairs, the Drader 245 will be of great interest to you. The small size and low weight of the machine make it ideal for reaching hard-to-reach areas.

The Drader 245 uses replaceable, heated welding tips.

The small welding machine is practical for short weld seams and repairs.

The tip and cylinder of the Drader 245 are heated.

The plastic is melted by contact with the hot tip.

The Drader 245 has no drive.

You feed the wire by pressing the handle.

The temperature can be adjusted.

There are three suitable welding tips for your application.

The metal tip is heated and melts into the plastic of your joining part through the oxidised surface.

In many cases, time-consuming preparation of the joint, such as when welding with an extruder or hot air gun, is not necessary.

The targeted heat input through contact with the hot tip keeps the surrounding area cool, allowing you to weld even thin plastic parts and plastic sheets.

The Drader 245 costs considerably less than an extruder.

With a low weight of only ~ 1.2 kg and its small design, the Drader 245 is convincing in many applications.

Ideally suited for short weld seams, for repairs and for filling holes and blowholes.

It is very easy to use and reliable results are achieved quickly.

Suitable for: PE and PP

230 V / 50 Hz

adjustable

LxWxH, without tip

You will receive your Drader 245 as a set in a sturdy transport case with three welding tips and accessories.

The Injectiweld feeds the wire automatically with a compressed air drive.

For longer weld seams and long-lasting work, we recommend the Injectiweld.

There are also more welding tips to choose from for the Injectiweld.

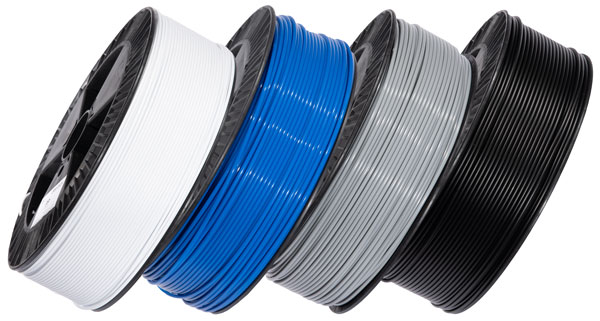

The spool with welding rod is put on the unroll stand and the rod is fed through the opening on the side.

The plastic rod can be unwound without twisting, tangling, or knotting.

The rotational movement is slightly slowed down, which means that the spool does not continue to roll uncontrollably but stops when the welding wire is no longer being pulled.

Acrylonitrile Butadiene Styrene

Acrylonitrile Butadiene Styrene / Polycarbonat

Acrylonitrile-Styrene-Acrylate-Copolymerizate

Polyamide / Nylon

Polycarbonate

Polyethylene

Polypropylene

Polypropylene EPDM

soft PP

Polystyrene

Polyvinyl Chloride

thermoplastic elastomer

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information