ABS

Acrylonitrile Butadiene Styrene

Thermoplastic elastomers are soft materials that have similar properties to rubber.

TPE can be formed and welded by applying heat.

Handles and household utensils as well as parts of consumer electronics are made of TPE and have a soft-touch surface.

In the automotive industry, TPE is used for insert mats, for the coating of control elements, trim parts, seals, spoiler lips and mud flaps.

TPEs have a useful temperature of -50 to 120 °C and have good resistance to chemicals, oils and alkalis.

TPE is soft like rubber and has a soft-touch feel.

TPE can be deformed and welded by applying heat.

TPE is a hydrophilic material. We recommend tempering the welding rod before processing for this reason.

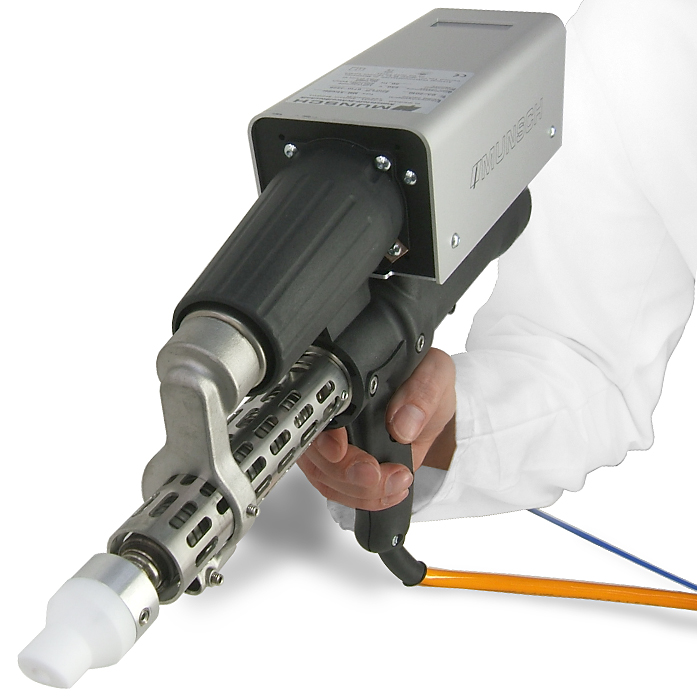

You can use welding equipment such as a hot air tool or use an extruder.

TPE can be cut and glued.

Acrylonitrile Butadiene Styrene

Acrylonitrile Butadiene Styrene / Polycarbonat

Acrylonitrile-Styrene-Acrylate-Copolymerizate

Polyamide / Nylon

Polycarbonate

Polyethylene

Polypropylene

Polypropylene EPDM

soft PP

Polystyrene

Polyvinyl Chloride

thermoplastic elastomer

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information