Repair kit for plastics

with a welding iron for the repair of broken and cracked parts

Advantages of our repair system

Repair broken and cracked plastic parts.

Fill holes and reinforce mechanically stressed areas with a metal mesh.

Suitable for thin plastics and hard-to-reach areas.

A repair kit for thermoplastics.

You will achieve convincingly good results with just a little practice.

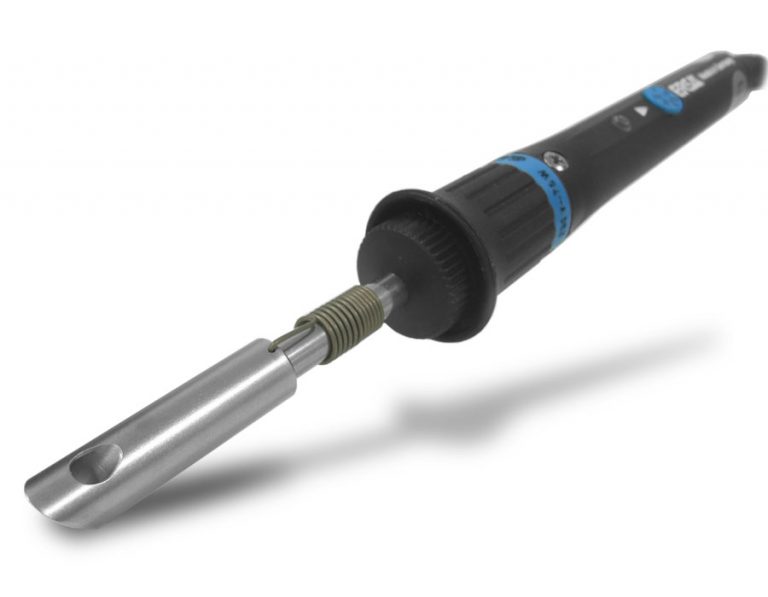

- Professional plastic welding tool

- Professional repair according to DVS 1110-3

- for thermoplastic plastics

- High quality of the weld

- Repairs and maintenance

- Bumper

- Attachment parts

- Motorbike fairing

- Household items

- Fill holes and blowholes

- weld thin plastics

- Low heat input into surrounding material

- lightweight and small

- easy handling

- quick to learn

- One-hand operation

- heated metal tip

Repair defective plastic parts, cracks, breaks and holes easily and reliably.

Quick to learn and quick to succeed.

Application

Use the hot welding tip of the welding iron to melt into the plastic, joining the two parts permanently.

You guide the welding iron with one hand. Use your free hand to fix the parts.

Weld the parts to themselves first without adding new plastic. This is already resilient. You can then fill the surface with repair sticks made of the same material.

You can melt a metal mesh into the plastic for reinforcement.

Convincingly easy to use.

Halten Sie die gerissenen oder gebrochenen Kunststoffteile passgenau aneinander.

Now tack the plastic by melting the hot tip into the plastic. Wait briefly until the plastic cools down and becomes solid again.

The position of the parts is now fixed. Repeat this tacking process at a distance of approx. 1.5 mm along the entire length.

The back is welded first, then the front. We recommend that you use a metal reinforcement mesh to reinforce the plastic if you can only weld from one side.

You then use the repair sticks made of the same material to fill surface depressions and apply new material for reinforcement. Heat both materials until they become viscous.

The tips have a feed opening for the repair sticks and a surface for smoothing.

The area can be reworked without any problems if the repair is not successful at first attempt.

Wie bereite ich den Reparaturbereich vor?

Clean the plastic part. Remove the paint from the repair area if it is a painted part.

Which plastic rod do I need?

On most plastic parts you will find a letter marking. This will tell you which plastic rod you will choose for this repair.

Welding is always done with the same type of material.

You can also make a test weld if you cannot find a marking or you do not want to dismantle the part.

Simply hold the hot tip on the plastic part, a repair stick on the tip and then slowly pull the tip away when both plastics have melted.

Hold the repair stick in position until the plastic is hard again.

Pull on the rod. You have now determined the right plastic if it holds.

What do I do after repair welding?

Clean the welding tip of plastic residues and allow the welding piston to cool down.

The repair area can be reworked after sufficient cooling time.

Smooth out any protruding plastic with sandpaper, a sharp blade or the weld cutter.

Now you can use the part again, mount it or paint it.

When do I need a metal mesh?

The mesh is used to reinforce the material and strengthen its mechanical stability in the area where you have melted the mesh into the plastic.

You also use the reinforcement mesh to reinforce brackets, to fill holes and to re-model missing areas.

Cut the mesh to size. Measure the size so that one centimetre of the mesh protrudes to each side.

Now use the hot tip to melt the mesh into the plastic. Start in the middle of the damaged area and work your way to the sides and then to the beginning or end of the repair area.

You can still smooth the surface when you have completely melted the reinforcement mesh into place.

Repair of a motorbike fairing with our mobile repair kit G-80.

What is the difference between the T-80 and the G-80 welding iron?

The T-80 welding iron has an electric and very precise temperature control.

The high-quality welding iron T-80 is used in the professional workshop.

The temperature of the tip is kept constant even if work is interrupted.

The precise temperature setting allows you to work even more accurately than with the G-80 welding piston.

The G-80 is gas-powered.

Use the G-80 welding iron on the road or when there is no power source nearby.

One filling of the gas tank with cheap lighter gas is enough for about 45 minutes of working time. You can set the flow rate on the piston (for welding the smallest level).

The G-80 welding iron has a convenient piezo ignition.

Stop the gas supply during a work break.

You will receive your welding iron as a set in a sturdy carrying case with repair sticks and accessories.

Delivery content

- Repair kit including:

- Carrying and storage case

- Welding iron

- Welding tip

- Manual

- Pusher piston

- Brass brush

- Reinforcement meshes (3 pieces 6 x 10 cm each)

- Repair sticks made of various plastics

Welding rod and alternatives for a repair kit

Plastic Welding Rod

Hot Air Tool

Injectiweld